How To Repair Casement Windows

How to Repair Sometime Windows

Updated: Aug. 27, 2022

Don't supervene upon casement windows—repair them

Learn how to fix common casement window problems. Free up a sticking window, supplant a broken creepo operator or sagging hinge, even supersede an unabridged sash. Repairs are unproblematic, and a lot cheaper than replacing the whole window.

You might also like: TBD

Overview

If you're thinking about replacing your casement windows because they're drafty, fogged up or merely difficult to open, consider this: Y'all can set up well-nigh of the issues yourself for a fraction of the toll of new windows—and it won't take you more than an hour or two per window.

In this story, we'll walk y'all through the fixes for the most common casement window problems. (Casement windows are the type that swing like doors.) You won't demand any specialty tools, and the materials are bachelor from most window manufacturers or online window supply companies.

Although your windows may look different from the ones shown hither, the techniques for removing the sash and fixing problems are similar.

Figure A: Casement Window Performance

When you turn the handle, the operator moves the crank arm and the split arm operator. The split arm operator so opens the window sash. Casement window operators come up in several styles. They may look complex, only they're easy to disconnect, remove and supervene upon.

Fix a stripped creepo handle

If you turn your window handle and zippo happens, the gears on your handle, crank operator shaft or both are probably stripped. Take off the handle and look for signs of wear. If the teeth are worn, replace the handle (available from manufacturers, window dealers, or search online for "window replacement parts"). If the shaft is worn, y'all can replace the whole operator (see the next prepare). But here's a home remedy to effort first.

Start past backing out the setscrew to remove the handle (some newer handles don't take setscrews and only pull off—and this prepare won't work). If you take a folding handle, mark where the setscrew is on the operator shaft when the window is closed and the handle is folded up. Remove the handle and file the shaft so the setscrew can lock onto the shaft (photo). The metallic is tough; it'll have about fifteen minutes to get a flat side. Or use a rotary tool with a grinder bit to speed upwardly the chore. Vacuum the shavings out of the operator and so they won't damage the moving parts.

Reattach the handle with a longer setscrew (sold at hardware stores). If you open and close the window a lot, this fix may not hold upwards in the long run.

Supervene upon a stubborn crank operator

If the splines on the crank operator shaft are worn or cleaved off, the gears don't turn hands or at all, then it's time to replace the creepo operator.

Don't worry if you lot tin't observe the make, model or serial number of the crank operator. Y'all simply need a picture. Snap a digital photo, email information technology to a window replacement parts company and the company will sell you a new one. Or mail the company a print photo. Yous can also wait at online catalogs at the replacement parts companies to observe an operator that matches yours.

To replace the operator, beginning take the crank arm off the sash. Most crank artillery slip out of a notch on the guide track on the sash (Photograph 1). Others are pried off with a flathead screwdriver, or a aqueduct is unscrewed from along the lesser of the sash. If the operator also contains a separate arm operator, unhook that, too (Photograph 2).

Slide or pry off the operator cover. If you have a removable cover, cut along the casement comprehend with a utility knife to piece through any paint or stain that seals it on the window jamb. Remove the trim screws along the height of the casement cover. Gently pry the comprehend loose (Photo three). Be careful—the comprehend tin can hands break! Unscrew the crank operator. Prepare the new operator in place, aligning it with the existing screw holes, and screw information technology to the jamb. If the embrace isn't removable, crank operator screws volition exist attainable on the exterior of the window.

Fix a sticking window

If yous have a window that drags against the frame when yous open it, close the window and examine it from the exterior. The sash should fit squarely and be centered in the frame. If not, you lot can adjust the position of the sash by slightly moving the swivel channel. (If the window is centered and square just still drags, see the next set up.)

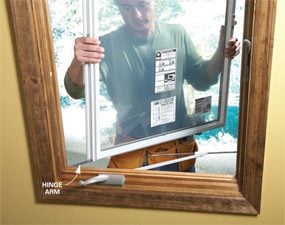

You can motion the aqueduct at the height or the bottom of the window, depending on where the sash is dragging (merely don't motion both channels). Start past taking out the sash (Photos 1 and 2). If the hinge arm is screwed to the sash, meet 'Replace a fogged sash' below.

Marking the swivel aqueduct location on the frame, then unscrew the channel. Fill the screw holes with epoxy (for vinyl windows) or forest filler (for wood windows). Filling the holes keeps the screws from realigning with their old locations when you reinstall the channel. Scrape the filled holes smooth before the epoxy sets. Place the aqueduct back on the jamb, almost i/8 in. over from the mark (move the channel away from the side of the sash that'due south dragging), drill 1/eight-in. pilot holes and then reinstall it (Photo three).

Replace a sagging swivel

Over fourth dimension, hinge arms that support heavy windows can start to sag, causing the sash to hit the frame in the lower corner that's opposite the hinge. First make certain the window sash is foursquare and centered in the window opening. If it's not, see the previous ready. To eliminate elevate in a window that fits squarely, supervene upon the hinge artillery at the top and the bottom of the window. You can buy the hinges at window hardware supply stores.

Remove the sash from the window. The swivel arms are located near a corner or in the middle of the window frame. Unscrew the hinge arms from the window, so install the new ones in the aforementioned locations.

Seal a drafty window: Conditions stripping casement windows

Weather stripping oftentimes becomes loose, worn or distorted when the sash drags or when the strip gets sticky and attaches itself to the frame, then pulls loose when the sash is opened. Windows have weather strip on the sash, frame or both. Regardless of its location, the steps for removing and replacing information technology are the same. Weather stripping is available from your window manufacturer. The window brand and glass manufacturer engagement are etched in the corner of the glass or in the aluminum spacer between the glass panes. You'll also need the superlative and width of your sash (take these measurements yourself).

If the weather strip is in good shape and loose in only a few places, like the corners, apply a dab of polyurethane sealant (sold at hardware stores) to the groove and printing the atmospheric condition strip into place. Otherwise, supervene upon the entire conditions strip. Start remove the sash and set it on a piece of work surface so you tin can access all four sides. If the weather strip is one continuous slice, cut it apart at the corners with a utility knife.

Starting at a corner, pull the weather strip loose from the sash. If the spline tears off and remains stuck in the groove, make a hook from potent wire to dig it out.

Work the new weather strip into the groove, starting at a corner. You'll hear it click as the strip slides into the groove.

If the window is stuck shut, it's likely that the weather strip is sticking. After you muscle it open up, spray silicone lubricant on a rag and wipe it on the weather stripping. Don't utilise oily lubricants; they concenter dust.

Replace a fogged sash

If you accept broken glass or fogging (condensation between the glass panes), you lot'll have to replace the glass or the entire sash. If the sash is in good shape (not warped or croaky), you can sometimes supersede just the glass. Telephone call your window manufacturer to see whether glass replacement is an selection and if a fogged window is covered under your warranty. You'll demand the information that's etched into the corner of the glass and the sash dimensions.

Contact a glass repair specialist to have merely the glass replaced (look nether "Drinking glass Repair" in the yellow pages or search online). Or y'all can supervene upon the sash yourself and save some of the cost. Order information technology through the manufacturer.

To replace the sash, first remove the erstwhile ane. You take this sash off by removing the hinge screws (Photograph i). For sashes that slide out, see 'Fix a sticking window' above. Remove any hardware from the damaged sash and install it on the new sash (this sash doesn't require any hardware).

Install the new sash by sliding it onto the hinge arms, then screw information technology to the hinges (Photo ii).

Required Tools for this Projection

Have the necessary tools for this DIY project lined up before you start—you'll save time and frustration.

Required Materials for this Project

Avoid last-infinitesimal shopping trips past having all your materials ready ahead of fourth dimension. Here's a list.

Originally Published: August 27, 2022

How To Repair Casement Windows,

Source: https://www.familyhandyman.com/project/how-to-repair-old-windows/

Posted by: mckinleybleall.blogspot.com

0 Response to "How To Repair Casement Windows"

Post a Comment